What is IATF 16949 Standard?

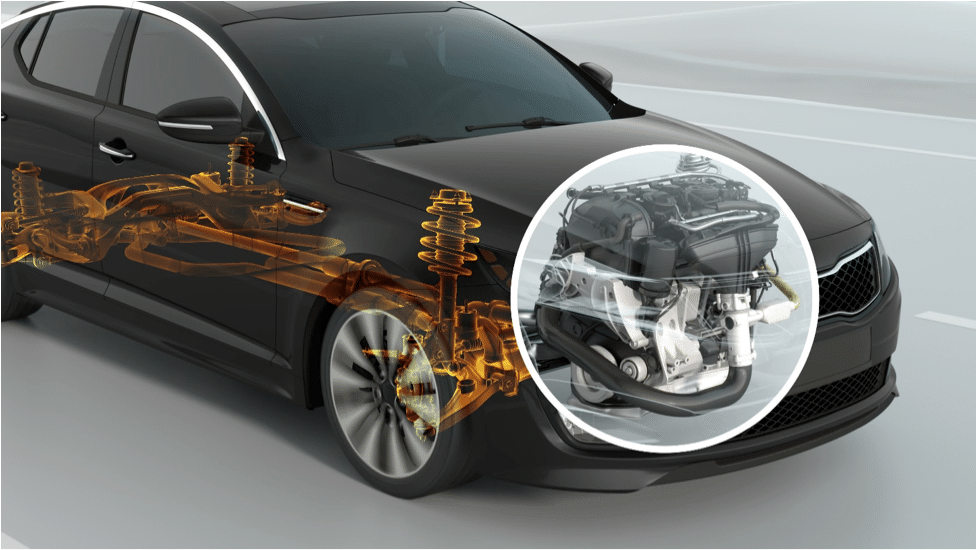

IATF 16949:2016 is an automotive quality management assurance system that is primarily focused on the automobile industry. The IATF 16949 certification presents a global standard to measure the effective capacity of the Automobile sector from production to supply and vice versa. The charter provides a clear-cut guideline on best practices in the development design, manufacturing, and production of automobiles as well as other related products. The IATF 16949 standard is the product of a well-researched assessment of the Automobile industry and includes sector players in the development of the action plan.

IATF 16949 Standard Presents a global effort by stakeholders in the automobile industry and related sectors to promote the best and well-developed management policies in the production of Automobiles, with adequate IATF 16949 training is an effort to secure a safety and quality measure. Renowned Automobiles manufactures in the world such as Ford, Fiat, Chrysler are all under the initiative. IATF 16949:2016 Standard reassures integrity and an automotive quality system control at all levels of production including the supply of modern Automobiles. The initiative has also been part of the International Automotive Task Force (IATF) policy frameworks.

The requirements for the IATF 16949:2016 certification includes the necessary sectors of the production requiring quality control and assurance

They include among others the following important areas:

- IATF 16949 Documentation on the development of effective production systems in automobile manufacturing and procedures of supply and distribution.

- IATF 16949 Quality assurance measures and responsibility of Automobile manufacturers for supply.

- IATF 16949 training provided, Informative and well-experienced staff and employees in the organization.

The few requirements of the IATF 16949:2016 certification have all translated into very fruitful benefits. International binding benchmarks have presented the initiative for companies in the automobile sectors towards quality management practice.

- All facilities engaged in the production of parts for automobile industry require an Automotive Quality Management System (AQMS) for IATF 16949 certification. Developing a comprehensive system to meet all the requirements of IATF 16949 for effective implementation to achieve desired results, a competent IATF 16949 consulting company or a competent IATF 16949 consultant is essential

- Any facility that wants a a robust system and ability to produce quality products and ensure safety for consumers must get IATF 16949 Certification

- IATF 16949 consulting companies prepare required AQMS to comply with all customers and regulatory requirements and the organization can demonstrate. Any company using this assistance can build a world class automotive part manufacturing company and go in for IATF 16949 certification

- IATF 16949: 2016 is a mandatory requirement for primary Tier 1 and Tier 2 Suppliers of Automotive products. Hence all Tier 1 and Tier 2 companies must get IATF 16949 certification and pave way for continual improvement in any facility

- IATF 16949 certification can be overwhelming at times but a competent IATF 16949 consulting company or IATF 16949 consultant can provide detailed explanation on the intent of the standard while developing an IATF 16949 compliant Automotive Quality Management System(AQMS) and any company can go in for IATF 16949 certification with such help

- A comprehensive AQMS can create confidence in end users, government, statutory and regulatory agencies and provide answers to all questions from Regulatory and Certification Body Auditors. Any company seeking customer confidence must get iATF16949 certification

- An IATF 16949 consulting firm provides the techniques for developing and implementing the QMS

- A consulting firm can provide internal auditing services to effectively conduct IATF 16949 conformity audits to fully prepare for IATF 16949 certification audits to ensure implementation

- IATF 16949 consulting companies or IATF 16949 consultants can minimize FDA audits and product recalls through robust compliant system development and effective implementation techniques

- Process of IATF certification starts with preparation of an Automotive Quality Management System (AQMS)

- Once AQMS is ready a thorough IATF 16949 Gap analysis is to be conducted to find what is lacking for IATF certification

- ISO Consultants assist in developing a comprehensive, AQMS to meet all requirements of IATF 16949 and third party Certification Body stage 1 audit requirements. The stage 1 audit from Certification Bodies vary depending on the selected IATF Certification Body which verifies the documented system meeting all IATF 16949 requirements or not

- An IATF 16949 consulting firm provides the techniques for implementation, and trains organization’s IATF 16949 internal auditors to become competent to perform internal audits or provides IATF Internal Auditing Services to audit all processes, all IATF 16949 Standard requirements and effective implementation of IATF 16949 Standard

- IATF 16949 certification seeking Facilities need to initiate corrective actions and witness that continual improvement is realized through control of nonconforming products/services.

- IATF 16949 certification seeking facilities need to implement the prepared AQMS for a minimum of 3 months and gather adequate data and record to show as evidence when seeking IATF 16949 certification

- Managements of the IATF 16949 certification seeking facilities need to conduct one full scale review of the entire AQMS and ensure its adequacy for their organization. Management Team needs to identify Action items to make corrections to any IATF requirement not being fulfilled

- Once a AQMS is ready, IATF Internal audit is performed and one full set of Management review takes place, the facility needs to contact a certification Body for certification audit

- Certification Bodies conduct Audit in 2 stages. During Stage 1, IATF 16949 audit will evaluate the documentation system and basic requirements of meeting IATF 16949 Requirements

- Certification Body will return for final audit where all IATF 16949 Requirements will be thoroughly audited to ensure that requirements are met and documentary evidence exists to demonstrate compliance

- Once certification Body is satisfied, recommendation is sent to accrediting agencies to issue IATF 16949 certification

- IATF 16949:2016 certification provides international recognition and approval in the manufacturing and supply of parts for automobiles.

- Creates a standardized sector rational to measure the effective capacity of industry players to produce high quality products that are secure for supply.

- Promotes consistency in effective management in the Automobile sector in order to ensure quality production is maintained at all angles to the letter.

- IATF 16949:2016 is informative in modern production practices that are cost effective and risk mitigated.

- IATF 16949 prescribes development of 19 documented procedures for use to produce a quality product

- Presents a simple and singular management strategy that covers a multi-dimensional organization to guarantee safe quality production and supply.

- Quality Systems Enhancement Inc. (QSE) is a Premier Consulting, Auditing and Training firm engaged in the field of IATF 16949 certification to international standards

- QSE has a unique 10 steps disciplined path for IATF 16949 certification which is insensitive to failure

- QSE has assisted over 700 facilities achieve IATF, ISO and other certifications

- One major difference is the QSE ensures that IATF 16949 Documentation and IATF 16949 templates are developed for implementing Automotive Quality Core tools which is not so common

- QSE ensures development of 19 documented procedures which is a mandatory requirement of the IATF 16949 standard

- In addition to Developing AQMS as per the requirements of IATF 16949 standard, QSE ensures that Customer Specific Requirements are documented and templates designed to ensure that organizations adhere to them to avoid findings in Customer Audits

- QSE’s IATF 16949 consultants unique document simplification tools result in smooth implementation to achieve IATF 16949 certification

- QSE’s IATF 16949 consultant identifies all processes from “Quote to Cash” in other words all activities from submission of quote, processing of the order, quality control, dispatch to customer and receive cash. All manufacturing and non-manufacturing processes are covered for IATF 16949 certification

- QSE’ s documentation covers all requirements of customers and other interested parties, statutory and regulatory requirements

- QSE’s IATF 16949 consultants provide unique simplified documented system is easy to integrate to other management systems

- QSE engages qualified and competent IATF 16949 auditors to conduct internal audits

- QSE’s internal audits are more stringent than Certification Bodies audits and will help companies pass certification audits with minimum nonconformities or no nonconformity

- 98% of QSE assisted facilities passed the initial IATF 16949 certification audit with zero deficiencies with a 100% passing rate first time around

- QSE’s IATF 16949 training program covers all the requirements of the standard including the implicit intent of the standard

- QSE’s IATF 16949 training involves all relevant employees which lead to effective implementation

- QSE’s IATF 16949 Document Simplification is unique comprehensive single level documentation which ensures effective implementation

- QSE’s IATF 16949 consultants provide documentation that is unique, simple, lean and easy to implement and sustains certification audits in the long run

- QSE’s IATF 16949 internal auditing services promote the unbiased assessment of AQMS implementation and the extent of implementation

- QSE’s IATF 16949 consultant ensures to provide implementation assistance or complete understanding of the documentation and IATF 16949 requirements

- QSE’s IATF 16949 Consultants provide training to top management in the management review format results in to no nonconformities against management review during certification audits.

- QSE does not simply tell our customers what to do during IATF 16949 certification process but assists them on how to do by holding hands till IATF 16949 certification is achieved

- QSE’s 10-step disciplined path for IATF 16949 certification achieves organizations certification in the shortest possible time. Usually within 5 months

- QSE provides post IATF 16949 auditing services if required and can take the disputes to the highest levels for resolution

- QSE engages all competent IATF 16949 auditors to conduct internal audits or supplier audits

- Alternatively, QSE provides IATF 16949 internal auditor training to members of the team in the team involved in IATF 16949 certification process

- President QSE, Baskar Kotte is an original and an active member of ISO/US TAG/TC 176, the Technical Committee that originally developed the ISO 9000 family of standards, ISO/US TAG/TC 207 which developed the ISO 14000 family of standards, ISO/US TAG/ TC 301 (TC 242) which developed ISO 50001 and ISO 19011 the Guiding standards for Auditing. Mr. Kotte also participated and provided input to the development of the current IATF 16949:2015, ISO 140001:2015, ISO 50001:2018 family of Standards and ISO 19011:2018 revised standards.

QSE has provided IATF training for OEMs like Mercedes Benz, KIA motors and Nissan. Packlite Suminoe, Corinthian Textiles, Toyo Tire Company Panasonic Industrial Devices and many more have sought assistance for IATF 16949 certification and IATF internal auditor training.

QSE can provide reference of any of our customers if required