Summary of ISO Internal Auditing Services Using Internal Audit Check Lists and Process Approach Application Lists

What is an ISO Audit and Who Needs it?

ISO internal Audits are unbiased, structured and documented evaluation of any given standards such as ISO 9001, ISO 14001, ISO 45001, ISO 50001, ISO 55001, ISO 22000, ISO 27001, IATF 16949, AS 9100, AS 9110, AS 9120, BRC, FSSC 22000, SQF, TL 9000, and recording the results.

QSE performs ISO internal auditing services in accordance with ISO 19011:2018 and with the application of the process approach to effectively comply with respective ISO Certification requirements or any other sector-specific standards and other management system standards such as Automotive Standards, Aerospace Standards, Food Safety Standards, Information Technology Standards, Information Security Standards, and Telecommunications Standards.

QSE’s ISO Internal Auditing Services, most of the times, results in no or very few nonconformities during ISO Certification or Sector Specific Certification or Surveillance audits.

QSE offers ISO Internal Auditing Services for all industries, all sectors, and all ISO standards.

What is the Solution?

QSE offers ISO internal auditing services in line with international guidance standard for auditing known as ISO 19011:2018. Invariably organizations that avail QSE’s internal auditing services emerge with no or very few nonconformities during final ISO Certification/ Sector Specific Certification or Surveillance Audits.

Benefits of ISO Internal Auditing:

Using ISO Internal Auditing checklists increases the confidence/reliability between departments, employees, management, and customers are enhanced. Organizations and businesses are granted the opportunity to implement and improve their processes. The process creates documented proof of any flaws or errors at any stage are made transparent. Ultimately, customer satisfaction will be enhanced. ISO Internal Auditing Checklists used as a tool that benefits organizations by measuring where they stand concerning ISO requirements, but more importantly, Internal Audits refer to the areas where they can improve. Process approach application during internal audits with effective ISO Internal Audit Check Lists and Prompt Lists identify compliance to Process Performance Indicators of each process to effectively maximize all process performance indicators

Quality Systems Enhancement, Inc. is a premier Consulting, Auditing, and Training Organization, established in 1992. For the last 27 Years, QSE has been assisting companies to achieve ISO 9001 Certifications, ISO 14001 Certifications, TS16949 or IATF 16949 Certifications, AS 9100 Certifications, TL 9000 Certifications, Food Safety Packaging Certifications, Forestry Chain of Custody Sustainability Certifications(SFI, FSC, PEFC) and providing Excellence Tools such as Operational Excellence, Overall Equipment Effectiveness, Total Productive Maintenance, Lean Sigma, and Design of Experiments to improve Bottom-line.

To achieve any ISO certification, every organization must perform internal auditing or internal audits on its own management systems such QMS, EMS, EnMS, OHSMS, ISMS, ITMS, and FSMS, prior to ISO Certification Audits.

QSE advocates at least one complete cycle of thorough all elements and all processes Internal Audits prior to any ISO Certification or ISO Recertification Audits.

QSE’s extensive experience in providing ISO Internal Audits comes from the Founder and President Mr. Baskar Kotte, who has been a member of Technical Committees. ISO US TAG 176, ISO US TAG 207 and ISO US TAG 301 (TC 242) since these Technical Committee inceptions in writing ISO 9001, ISO 14001, and ISO 50001 standards. He has also been a member of the Technical Committee, which developed ISO 19011:2018 Guidance Standard for conducting audits on Management System Standards of Quality, Environmental, Energy, Information Technology, Information Security and Occupational Health and Safety.

Knowledge acquired from several years of association in writing standards, writing, interpretation guidance, standards and writing the intent of the standards provides ammunition to QSE trainers, consultants and auditors to perform professional, evidence gathering and thorough ISO Internal Audits which are more stringent than certification audits. QSE has performed over 2000 ISO related Quality System Audits, Environmental Management Systems Audits, Energy Management System Audits and Occupational Health and Safety Audits.

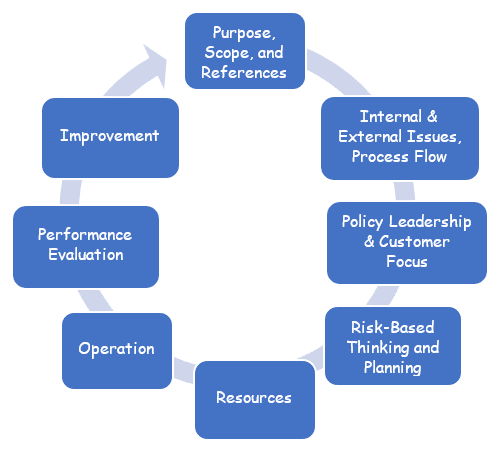

QSE’s ISO Internal Audits demonstrate effectiveness required for a complete implementation through process approach and risk based application.

QSE performs one full cycle of entire QMS, EMS, EnMS, OHSMS, ITMS, ISMS and FSMS Internal Audits and conducts audits on all key processes on all shifts.

QSE developed ISO Internal Auditing Services due to our customer demands based on the following partial list of advantages:

- Eliminates unnecessary burden on volunteering Internal Auditors.

- Eliminates the need for retraining internal auditors when new approaches such as Process Approach and Risk Based Thinking, are introduced.

- Minimizes nonconformities related to ineffective audits during the third-party ISO 9001:2015 audits.

- Promotes improvement of the system and not just doing it for external audits, since we do more thorough value-added audits.

- Do not have to pull your valuable resources to conduct audits.

- Management Systems are maintained in a state of readiness always and not just for meeting ISO Certification Auditors.

- Realize intended fullest benefits of System Implementation since QSE conducted ISO Internal Audits cover internal procedures, all manufacturing and non-manufacturing processes, all management standard requirements for implementation effectiveness in a thorough manner.

QSE can be the perfect answer for all your questions on auditing. Internal Audit is a mandatory requirement in all standards, hence Internal Audits is mandatory for every company that goes in for certification. The following are few examples of who should benefit from QSE’s ISO Internal Auditing Services:

- Any company willing to achieve ISO certification to ISO standards such as ISO 9001, ISO10993-1, ISO 14001, ISO 22000, ISO 27001, ISO 45001, ISO 50001, ISO 55001, IATF 16949, AS 9100, AS 9110, AS 9120, ISO 13485, ISO 15189, ISO 15378, TL 9000, MDSAP and GFSI recognized Food Safety Standards such as BRC, IFS, FSSC 22000 and SQF.

- Any company that wants to sail through their ISO related certification audits with minimum or no nonconformities during certification body audits.

- Any organization interested in passing ISO certification audits with no nonconformities against internal audits during initial ISO certification audits, any ISO surveillance audits and any ISO recertification audits.

- Any facility seeking realistic benefits and improvements through a comprehensive ISO Internal Audits.

- Any organization seeking to realize intended benefits of ISO certification through rigorous ISO Internal Audits which identify all implementation difficulties NOT just to hang the ISO certificate.

- Companies facing problems in keeping trained internal auditors

- Companies interested in Bottom-line Improvement and wishing to enhance customer satisfaction through Problem Solving because of QSE’s intensive ISO Internal Auditing Techniques.

- Companies who wish to minimize waste and nonconformities in both manufacturing and non-manufacturing areas through tough ISO Internal Audits which highlight all internal/external issues.

- Any company willing to be a certified partner in any supply chain or be a certified supplier.

- Any company interested in having continual improvement in their business operations.

- Any company in manufacturing or service sector, small or big company may avail our services for performing internal audits on a periodic basis for smooth certification and sustenance of certifications through surveillance audits.

- Organizations seeking to apply process approach right way and having difficulties in accurately designing process approach application during ISO Internal Auditing.

- QSE uses competent ISO Internal Auditors skills in applying the process approach and risk based thinking

- QSE ensures experienced ISO Internal auditors with relevant industry background to ensure top management confidence in accepting identified improvement areas with no disputes and addressing them

- QSE has developed effective evidence gathering tools during ISO Internal Audits to ensure manufacturing process audits, product audits, thorough management system audits are accurately conducted, evidence gathered and disseminated

- QSE conducted Internal Audits helps create ability of companies and businesses to control every procedure and to get members of staff to work together in finding solutions to identified problems

- Internal Audit conducted by QSE helps Improve the efficiency and effectiveness of their operations

- QSE assigned ISO Internal Auditors ensure relevant regulatory and statutory requirements are fully evaluated and ensure that the evidence is gathered to show compliance

- QSE designated ISO Internal Auditors ensure that the established management systems such as QMS, EMS, EnMS, OHSMS, ITMS, ISMS and FSMS are fully adhered to respective certifiable standards

- QSE’s unique evidence gathering methodology includes that all customers required, the organization required, regulatory required and ISO Management System Standards’ required records are retained as documented information

- QSE conducted ISO Internal Audits determine whether the organization’s management systems conform to:

- Planned arrangements

- Requirements of selected ISO standards

- Requirements established by the organization or company

- Customer specific requirements

- Any other applicable statutory and regulatory requirements

- Industry specific requirements such as automotive core tools, telecommunications metrics submission, and aerospace PEARS.

- QSE conducted Internal Audit directs the management’s attention to key business issues

- QSE’s Internal Audit gives early notice of potential problems so that the management can act to resolve

- QSE applies the Process Approach the right way to all processes of the facility to meet the requirements of the standard

- QSE Conducted ISO Internal Audits seldom leave room for any nonconformities during a final audit/ or a surveillance audit

- QSE engages qualified and competent auditors to perform Internal audit on any facility for any standard

- Unless otherwise specified, QSE conducts a through and stringent audit on all elements of the standard clause by clause and includes all sub clauses during ISO Internal Audits.

- QSE ensures adequacy of any required documented procedures or documented processes during internal audits for effective compliance to selected standard

- QSE submits a detailed report of the Audit Findings clause by clause and a summary report notating the number of nonconformities by each clause for macro action for further ISO Internal Auditing

- QSE has perfected the art of creating a template pertinent to ISO Internal audits of each standard.

- QSE utilizes tried and tested templates in conducting ISO Internal Audit.

- QSE has perfect project management steps and templates for following all requirements stated in the standard such as Audit planning, Audit requirements, Audit scheduling Audit notification etc.

- QSE makes it evident to auditees that the audit is on the management system and not on individuals. This helps ease the anxiety of auditees during an audit.

- QSE’s interviewing and questioning are for evidence gathering.

- QSE engages humanistic elements in auditing and avoids conflicts.

- QSE obtains auditee acknowledgment prior to documenting a nonconformity.

- QSE conducts opening meeting at the beginning and the closing meeting at the end and provided daily debriefing.

- QSE’s ISO Internal Audits are more stringent than certification audits to minimize nonconformities during certification body audits or third party audits.

- QSE has developed a unique Process Approach Audit Prompt List sheets for every ISO standard, which require processing approach application to conduct ISO Internal Auditing.

- A Key outcome of QSE conducted ISO Internal Auditing is a detailed report on all nonconformities and all conformities by clause by clause of the ISO standard.

- QSE identifies any repeated nonconformities separately to give management a view of the extent of the problem

- QSE obtains auditees’ acknowledgments of all identified nonconformities during ISO Internal Audits to avoid any future audit deficiencies disagreements.

- A major outcome coming from QSE conducted ISO Internal Audit is a detailed Audit Report.

- Large number of nonconformities unearthed by QSE’s ISO Internal Audits will prove to be helpful for following:

- Nonconformity identified by QSE conducted ISO Internal Audit do not show up as nonconformity in an ISO certification audits or ISO surveillance audits or ISO recertification audits

- Minimize documentation related disconnections

- Involve all process owners and drives improvement across the organization

QSE Serviced industries include manufacturing, aerospace, automotive, chemical, food, forestry, healthcare, hospitals, laboratories, logistics, medical devices, metals, packaging, paper and pulp, pharmaceutical and telecommunications.

QSE performs ISO Internal Auditing Services to ISO Management System Standards such as Quality, Environmental, Energy, Food Safety, Information Technology, Information Security, and Occupational Health and Safety.

QSE provides ISO Internal Auditing Services for ISO certification to ISO standards such as ISO 9001, ISO 13485, ISO 15378, ISO14001, ISO 22000, ISO 27001, ISO 45001, ISO 50001, ISO 55001, IATF 16949, AS 9100, AS 9110, AS 9120, TL 9000, MDSAP and GFSI recognized Food Safety Standards such as BRC, IFS, FSSC 22000 and SQF.

The time for ISO internal audits depends on specifics on the Audit Notification related to the number of shifts, processes, ISO management system to be audited and number of employees.

It may not be mandatory if the facility is sure of compliance with some elements of the standard and audit may be required for few other elements alone. But it is always preferable to conduct one full cycle of all elements and all process audits at least once in a three-year term. ISO Internal Audits are to be performed based on the importance of the activity, unless there is another requirement conflicts with it.

Yes. All relevant credentials of ISO Internal Auditors will be submitted to the organization prior to conducting the ISO Internal Auditing.